|

|

|

|

NERO  Rocket motors Rocket motors  Penta

Series Rocket Motors Penta

Series Rocket Motors |

|

Penta

series rocket motors |

|

|

|

|

| The Penta motors are based on ammonium

perchlorate binded with polyurethane. These propellants are classified by TNO/PML. In 1994, the E-38 rocket of

NERO-Eindhoven was the first rocket to fly with the Penta-alpha motor. At the moment these motors are also in use

by other NERO rockets, for instance the H10-project and by the Belgian society GEA. Both the Penta Delta and the

Penta Epsilon will power the altitude record rocket H10. |

|

|

|

|

1. |

Common [Top] [Contents] |

|

|

|

The Penta motors are based on ammonium perchlorate binded with polyurethane. These

propellants are classified by TNO/PML. In 1994, the E-38 rocket of NERO-Eindhoven was the first rocket to fly with the

Penta-alpha motor. At the moment these motors are also in use by NERO-Haarlem, for their H7 project, and by the Belgian

society GEA.

At the moment we are also considering the Penta-Beta, a TG-10 replacement, and Penta-Delta,

a Caribou replacement. For the GEA we are also working on a refill grain for the Isard.

Below the thrust of the Penta motors in relation to other used rocket motors within

the NERO. |

|

| Motor |

Thrust |

Propellant |

Duration |

Length |

Diameter |

Used in |

| Penta 500 |

520 Ns

|

0,3 kg |

3,0 s |

211 mm |

60 mm |

H7b, H7c |

| Penta 1000 |

1070 Ns |

0,53 kg |

1,1 s |

- |

- |

H8a |

| Penta Alfa mod 1 |

2150 Ns |

1,1 kg |

2,5 s |

548 mm |

70 mm |

H6b, H6c,

H7a - H7c |

| Penta Alfa

mod 2 |

2150 Ns |

1,1 kg |

2,5 s |

548 mm |

70 mm |

H7d, H7e |

| Penta Gamma |

3750s |

- |

3s |

- |

100mm |

H9a |

| Penta Delta mod2 |

10.000Ns |

- |

5s |

850mm |

100mm |

H10z |

| Penta Epsilon mod2 |

18.000Ns |

- |

6s |

1005mm |

100mm |

H10z |

| TG-10 |

3000 Ns |

1,5 kg |

1,2 s |

- |

- |

H5, H6a

|

| Koudou |

120 Ns |

- |

0,6 s |

- |

- |

H7a |

| Thrust-18 |

1840Ns |

1,480 kg |

0.95s |

354.5mm |

100mm |

H10a, H11a-e |

|

|

|

24.2KB |

Meroc Penta-Alpha rocket motor with igniter assembly |

84.6KB |

Static test setup for a static test of the Penta-Alpha 2200 Ns motor. Thrust and

pressure are measured during burning. Also shown is a thermocouple for casing temperature registration. |

77.7KB |

Static test for the Penta-Gamma 4200 Ns motor. Thrust and pressure are measured during

burning. |

|

Static test of the Penta 1000 motor |

|

|

|

2. |

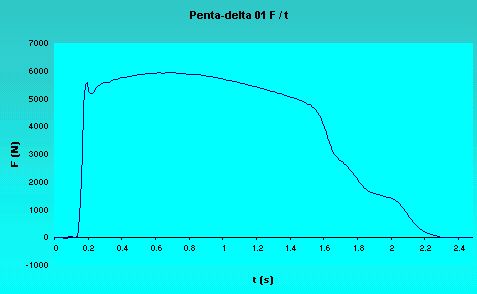

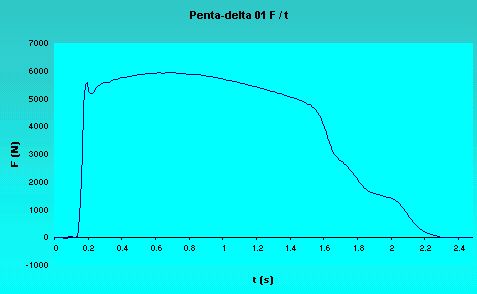

Penta Delta (second stage H10)

[Top] [Contents] |

|

|

|

The Penta-Delta is of standard MEROC

design with the threaded aluminium tube, aluminium closure and steel nozzle with graphite insert. The most impressive

thing about it is its size: 100 mm diameter and 800 mm long. This is the motor that powers the second stage of the H10.

November 12th, 1999 it was tested for the first time at the ASK 't Harde,

a military shooting range. While NERO was setting up the gear, artillery troops where instructed how to fire live TOW

missiles. Even 5 miles away you could clearly hear the impact of the warhead.

Before the test of the full motor, single grains were tested in a separate test motor.

Since the standard NERO C* test motor was too small a special test motor was made for these grains.

The motor tested two types of grains, a regular fast grain and a specially prepped

slow grain. When they test within specs the Penta-Delta should also perform as designed. |

|

|

|

Igniter from the Penta Delta motor |

|

Mounted igniter |

|

The Penta Delta motor in the test bench |

|

idem |

|

Nozzle before use |

|

Nozzle after the motor has burned |

|

|

|

As one can see in the space shuttle, the best way to ignite a rocket motor is to use a

flame thrower. For the Penta-Delta the flamethrower is accessed through the front closure. A boosted professional

e-match is used to ignite the flamethrower which is pretty much a small rocket motor. |

|

After these two tests proved successful and within specs the Penta-delta itself was

mounted on the test bench. This motor also features the MEROC fast ignition system which makes the motor ignite at the

push of the button. The first six pictures from the sequence down below are consecutive frames from the video tape and

only 1/24 second apart. It would be nice to put the sound here as well as there is no way I can possibly describe how

awesome it was. |

|

|

|

|

|

Since all NERO experiments are conducted on the NERO measuring equipment, it is possible

to generate great graphs of the thrust curve and pressure curve after the information is downloaded from the computer.

In the graph to the right you can see the calibrated graph drawn with MS Excel. Please note the little step in the

tail-off of the burn. This was caused by one slightly smaller grain which ofcourse burns out faster then the rest.

|

|

|

|

The Penta-delta motor performed as expected. The rocket it was designed for should have

received a great power plant but since the design of the rocket changed it will also get a new motor, the Penta-epsilon.

The Penta-epsilon will only be a slight upgrade of the Penta-delta with use of new materials and only a moderate larger

amount of propellant and a bi-thrust composition. |

|

|

|

3. |

Penta Epsilon (first stage H10) [Top] [Contents] |

|

|

|

With the test of the Penta Epsilon on Friday 6th of July 2001, the record for the most

powerful NERO-motor has been broken. Previously this record was held by the Albatros motor that burned 45kg Sink-Sulphar

in 1987 and provided a thrust of 16.000 Ns. The Penta Epsilon motor set that record to 18217 Ns.

The ignition delay was very short and the motor burned very stable during approximately six seconds, a bi shorter

than hoped for. Even at a distance of 300meter, the noise of the motor (with 8,8 kg propellant) could be heard easily.

The flame from 3 meter and the exhaust plume from 15 meter, the test was very spectacular. |

|

|

|

The motor sustained the test very successfully. There was some erosion in the nozzle

just behind the graphite inlay. Also the graphite in the throat was eroded. The diameter eroded from 30mm to 30,7 mm.

Finally a thin layer (0,25 mm) was placed upon the nozzle, so this resulted in a throat of 30,2 mm. |

|

|

|

|

|

Thrust curve of the Penta Epsilon. As easily can be seen, that the booster-layer

burns first. After that the sustainer-layer takes over. |

|

|

|

The slightly short burning time can be explained by the outside temperature. Te high

temperature caused the motor o be 20 degrees warmer than expected. The temperature sensitivity is 5%/Degree Kelvin,

witch resulted in a 10% shortened burning time. The specific impulse was 210,7 sec, the total impulse 18217 Ns.

The pressure increase due to the erosive burning, was more steep than expected. This was also expected to be caused

by the high motor temperature.

Furthermore the heat resistance from the hard paper liner was extremely well, better than we expected. |

|

|

2.9 MB |

Look at a movie of the static test of the Penta Epsilon. |

|

|

|

The bulkhead and nozzle of the Penta Epsilon |

|

The grain with dual propellant |

|

The nozzle before testing |

|

Filling the motor |

|

Preparing the test-bench |

|

The nozzle after testing |

|

Close-up of the nozzle after testing |

|

The Penta Epsilon in the old test-bench |

|

|

|

|

|