Star Grain Motor

|

| The SG grain shape was developed to fulfill the needs for a powerful booster motor for larger projects. A typical booster has a burn time of less then one second and therefore a long thin motor was needed with a large initial propellant area. |

1.

|

The caster is used for several reasons. It gives a platform to work from, it enables you to efficiently degas the propellant and the incorporated jack facilitates extraction of the mold. The heat cord wrapped around the bottom part also gives you the opportunity to preserve a good working temperature which would work fine with a shaker or vibrator to facilitate the degassing of the propellant. Once the grain is properly casted, the vacuum is released until the binder in cured. |

3.

The test was done on the NERO test bench. This computerised testbench is usually fitted with the C* motor, but it readily accepts other motors with standard thread.

Readings from the static test were then iterated to pressure readings, since the relatively small test motor had no pressure sensor slot.

- Simulation is the blue line. It's derived from the computed surface of the grain at each step in the simulation. The surface is then fed into the nozzle ratio equation and finally into the pressure equation.

- Measurement data is the red line. It's a pressure curve, iterated from the thrust curve of the first static test of the SG38 motor.

By changing the n and a propellant parameters, both curves can be aligned and the found values for a and n will be used for simulations and computations of other models with the same propellant.

If you feel offended by the name "SuperGrain", please don't. This name was adopted after the first static test and we were all very excited about the result. It will be changed appropriately when time comes.

4.

At this moment the I400 QSG38 is fitted with the Quickstart(tm) ignition system which ignites the SG38 in 400 milliseconds to nearly 90% of its maximum thrust.

The initial "weak" propellant formulation will be substituted for a more powerful one on the next static tests, both to enhance performance and to test material strength.

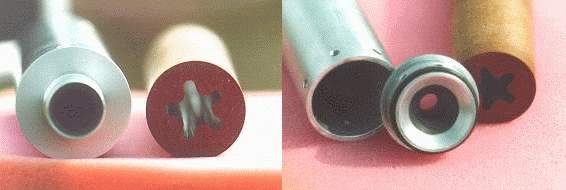

Various pictures of the SG38 test motor (with thanks to Eadrik Wildeboer for the pictures).